(Residual) Stress Shortens Lifetime

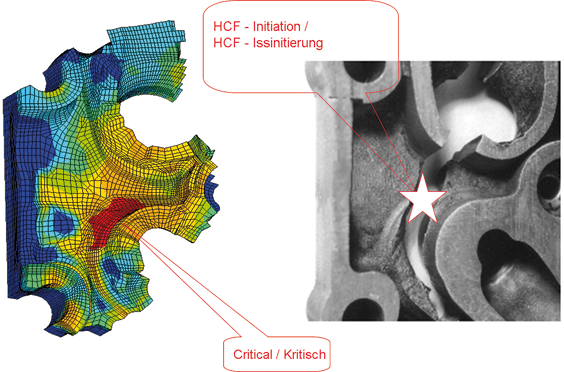

Especially in the recent past, numerous diesel cylinder heads have been developed that showed cracking problems in operation for no apparent reason. Frequently, the cause was determined to be ignoring the residual stresses coming from the manufacturing process!

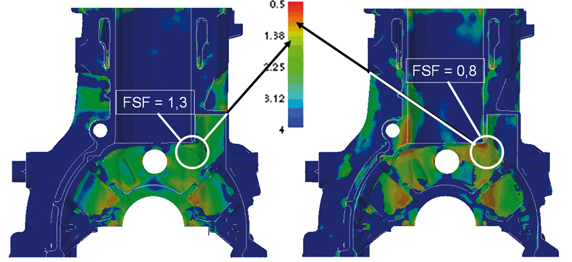

These residual stresses are a kind of pre-loading of the component. In operation, they are superimposed with the load stresses. If the residual and load stresses have the same sign, they compound each other. In this case, the residual stresses reduce the level of loading that can be tolerated. If the residual and load stresses have opposite signs, an effective increase in the tolerable loading is reached.

In practice, the residual stresses can achieve levels as high as the yield strength. That is why residual stresses from manufacturing processes have to be considered when designing components for durability. This is also true for cast or heat treated components.

* Courtesy of Ricardo, UK and FEV, Germany