Optimizing the Production of Structural Components

Rolf Gerschwinat, ALCOA, Soest; Dr.-Ing. Götz Hartmann, MAGMA, Aachen

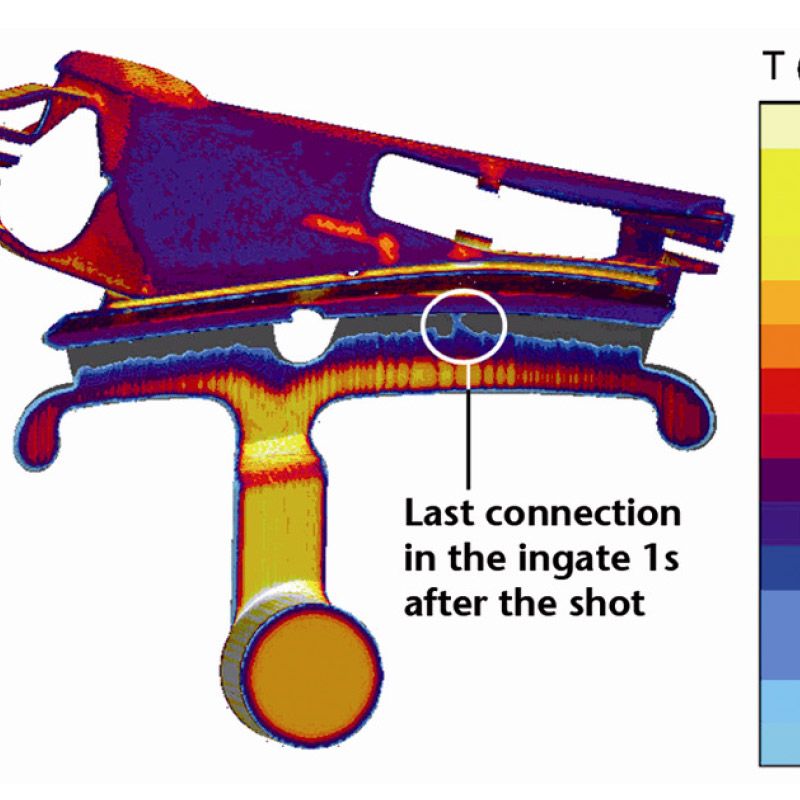

Structural components made of aluminum, magnesium, or zinc are crash-relevant and load-bearing components, and in many cases have visible surface areas. Consequently, the requirements on rigidity and extensibility are very high; the castings must be free of porosities, blisters, and weld marks. Additionally, the often required heat treatment demands high quality castings. An optimal die filling process is very important for these thin walled and large die casting components, e.g. the header or the main pillar of the Chrysler Crossfire convertible top, casted by Alcoa Germany for the Karmann GmbH.

[...]

Please read the complete publication in the linked PDF.

Engineering

Support

MAGMAacademy