Process Optimization for an Energy Efficient Heat Treatment of ADI

Erik Hepp, Marat Dzusov, Dr. Wilfried Schäfer

Abstract

Austempered ductile iron (ADI) materials show a good combination of mechanical properties, with high tensile strength levels (800 - 1600 MPa) and an elongation at fracture of up to 10%. Due to its high fracture toughness as well as high fatigue resistance, ADI is a very attractive material group for applications under cyclic loads. However, the material properties are very sensitive to the applied process conditions during heat treatment. The basis for a substantial increase in the application of ADI materials in the industry requires the establishment of a predictable and robust process design.

Here, an integrated process simulation of the heat treatment process coupled to required information about the as-cast quality of the component would aid in understanding process dependencies and defining a robust process window. For the austenitization step, the simulation can be used to determine the needed treatment times and temperatures.

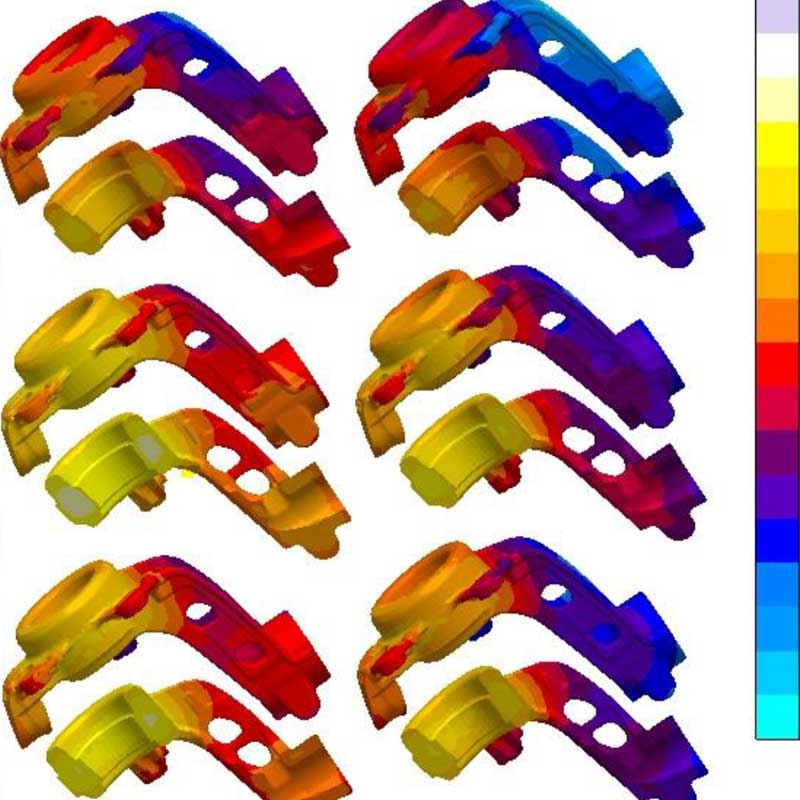

In the process simulation software MAGMA5, a new fast and efficient algorithm for heat exchange between thermally coupled diffusely radiating interfaces has been implemented and can be used for heat treatment simulation. The accuracy and computational performance of this new radiation model for the heat treatment of ADI is illustrated here for a real industrial suspension part. The steering knuckle is heated in a typical heat treatment box. Surface-to-surface radiation between the parts and with the surrounding furnace results in inhomogeneous temperature distributions.

Integrated capabilities to perform virtual experiments and automatic optimization are used to determine optimal process conditions to meet both the quality requirements and the minimum required treatment time during austenitization.

Please read the complete publication in the linked PDF.