Aallied Die Casting: 70,000 ppm to 150 ppm

How One Die Caster Uses Technology to Profitably Produce a Challenging Automotive Casting

History

This casting is an automotive transfer case housing, which is used on a full-sized four-wheel drive truck. Prior to its arrival at Aallied Die Casting of Rutherfordton, North Carolina, a division of RCM Industries, this project was experiencing a fallout rate of over 7% (70,000 ppm) at the customer. This resulted in the customer needing to leak test 100% of the castings; those that failed leak testing were impregnated. Due to the high volume of the casting, a solution was needed to reduce costs associated with the unforeseen issues. This is when Aallied Die Casting was given an opportunity to deliver a better quality product to the customer.

Aallied Design

Aallied was placed into an intense scenario involving high profile customers, which meant that their only option was to design a way to success. Using all the advanced tools at their disposal, including MAGMASOFT®, combined with their collective knowledge and experience, the Aallied team had the confidence and the capabilities necessary to charge forward without reservation. This was one of the key factors why this project was such a success.

The Aallied team has been using MAGMASOFT® for 16 years, and they utilize this engineering tool on every project they undertake. By working together within their multidisciplinary team, they are able to consider all of the parameters that are used in the real world, allowing them to have the utmost confidence that their results are as close to optimal as possible.

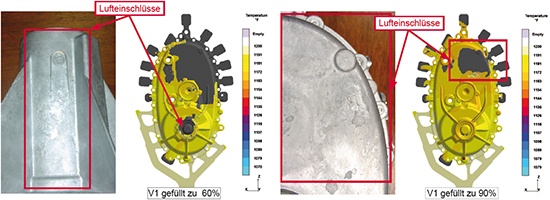

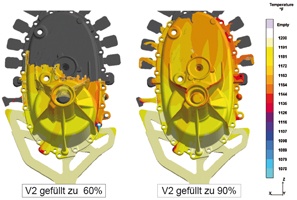

After the die arrived at Aallied Die Casting, they analyzed the runner and gating system using MAGMASOFT®. The simulation results immediately showed numerous trapped air pockets during the filling of the casting (Figure 1). The Aallied team went to work optimizing the gating and runner design, to reduce the entrapped air pockets and achieve a more uniform flow front. With small changes to the runner and gating system, the team was successful in reducing the trapped air indicated in the MAGMASOFT® simulation (Figure 2).

Further optimization was achieved utilizing other MAGMASOFT® results. After reviewing the air pressure result, they noticed the transferred design did not have adequate venting. The optimized gating system provided a more uniform flow front and improved the initial air pressures. However, uniform flow alone was not sufficient to eliminate the high air pressures in the die cavity, and properly placed chill vents were added to correct this issue.

All of this optimization allowed Aallied to eliminate the need for the squeeze pins which were present in the previous die caster’s design. This reduced the complexity of the tooling. It also reduced the complexity of the process, making it more robust and reliable. The improved robustness was clearly shown in the resulting reduction in fallout.

Improvements

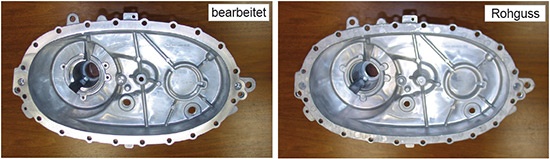

After implementing all of these design changes, a massive improvement in casting quality was experienced. The customer was able to eliminate the 100% leak testing and impregnation. This resulted in cost and time savings for the customer, and the end result was that the fallout at the customer currently stands at 0.015% (157 ppm) over the last 6 months of production. This represents a total of approximately 21 defective parts out of over 130,000 shipped castings. This is even more impressive considering that the part is also heavily machine by the customer. There is no secondary processing, no machining, no 100% X-ray, and no 100% leak testing performed at Aallied. An example of the machined casting is shown in Figure 3.

* Text and images courtesy of Aallied Die Casting, USA