Chongqing Dajiang Millison Optimizes Die Casting Bracket Production

For Chongqing Dajiang Millison (CDM), the targets in production are clear: fast product development, reliable manufacturing processes and optimized product yield. These objectives apply for a great variety of cast parts, both new and in regular revision. Recently, the production of an aluminum automobile bracket was due for optimization.

Previously, the bracket was successfully produced using a single cavity die. However, the quality of the casting was affecting the functionality of the end product, with some castings subject to breakage and others showing porosity defects revealed during machining. While these problems were one subject of the revision, the profitability was also to be improved by developing a new, two-cavity die and by optimizing the production process as a whole.

CDM engineers started by analyzing the quality issues. To confirm their assumptions, identify root causes and provide tangible solutions, CDM engineers employed MAGMA5. The combination of the existing runner and gating layout together with fast filling velocities was presumed to generate air entrainment, resulting in gas porosity. The runner and gating design was also assumed to locally impede the effectiveness of the intensification pressure, leading to the defects observed during machining. The root causes for the breakage problems were attributed to cold shuts and poor fusion of metal fronts, caused by locally insufficient melt temperatures.

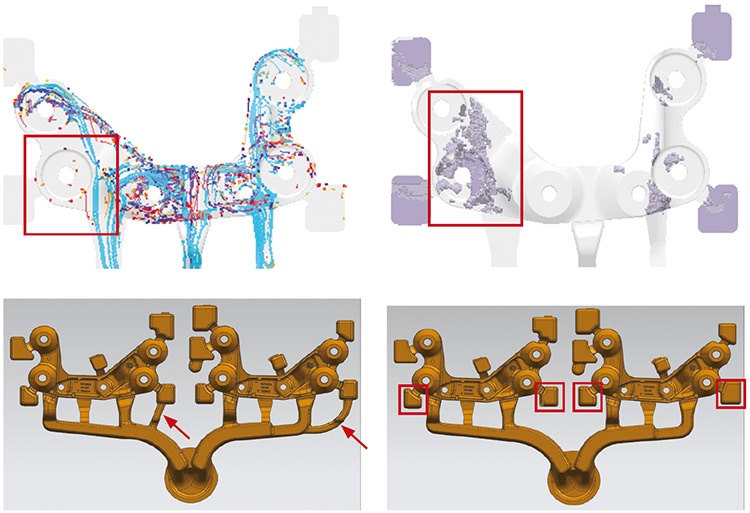

First, the criteria for gas inclusions in the critical area were found to be significantly higher than elsewhere in the casting, indicating the danger of gases being entrapped by the melt front. ‘Tracer’ particles visualized the flow paths and helped to understand why the flow patterns led to inadequate venting and entrainment of air by the metal during the filling of the cavity.

Based on the agreement between simulation and reality, the engineers proceeded by virtual experimentation to develop and test two modified runner designs for the two-cavity die: in Version 02, two additional runners were added to the gating system to modify the flow behavior, with the goal of improving the venting and increasing the melt temperatures in the critical areas for cold laps. Version 03 featured enlarged overflows to aid the escape of entrapped gases and help colder metal move more easily into the overflow.

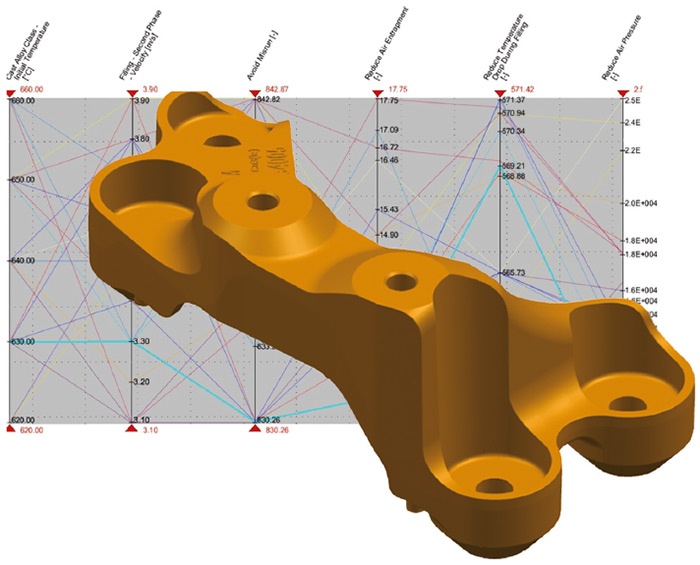

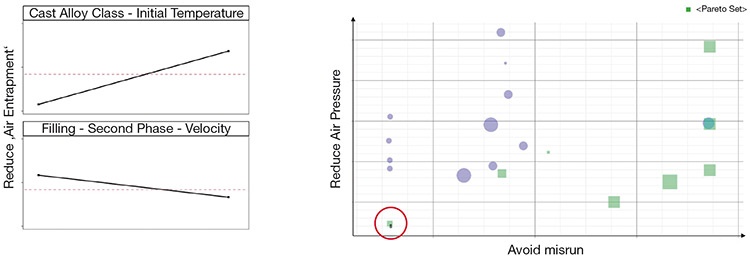

The results for both versions showed substantially decreased air entrainment. Especially Version 03 proved effective in achieving higher metal temperatures in the region critical for cracking. However, the engineers continued their work using the new capabilities of autonomous optimization in MAGMA5 Rel. 5.3 to establish robust production parameters. Two parameters were varied autonomously by the software: the casting temperature, which was varied from 620 °C to 660 °C, and the second phase piston speed, which was varied from 3 to 4 m/s. The software was set to follow four, partially conflicting, objectives: 1. minimization of air pressure in the cavity, 2. minimization of air entrapment in the casting, 3. minimized temperature drop during filling and 4. avoiding misruns. The software was used to automatically create a statistically relevant set of simulations varying the specified parameters, and to run and test the resulting 20 designs autonomously.

In MAGMA5, the CDM team used the Assessment Perspective to evaluate the results of all the investigated designs. The ranking of the designs according to their fulfillment of the four specified objectives, together with scatter charts visualizing the trade-offs between the targets, helped them to focus in on those designs that were most interesting. Assessment of the Main Effect Diagrams provided valuable information regarding which parameters (e.g. initial temperature and 2nd phase velocity) most significantly influence the tendency to entrap gases and form misruns during filling of the castings. Finally, the engineers used the Parallel Coordinates Diagram to select a process set-up that would provide the best solution for a robust process.

Using this analysis, tooling was produced and tested. In the resulting casting no failure was observed during testing, and x-ray inspection showed nearly no remaining porosity due to entrapped gases, so that the castings were within the specification. With the two-cavity die, the scrap rate could be significantly decreased to 2%. The annual production of 100,000 quality parts now saves 20 tons of raw materials and an estimated total of 95,000 to 110,000 US$ per year.

As this example shows, optimizing tooling design and process conditions with the methodology of virtual experimentation and autonomous optimization is an important step for CDM. The company will continue to use MAGMA5 Rel. 5.3 to further speed up R&D, establish robust and optimized casting processes, and expand their product portfolio.

Chongqing Dajiang Millison Co. Ltd., located in Banan, China, was founded in May of 2001. Millison has earned their customers’ recognition through accurate production and high quality products. Today, the company’s production bases are two plants in Chongqing and Xiangyang. Its annual output of aluminum castings reached 40,000 tons in 2013. Among others, they produce automotive die castings such as engine blocks, automatic transmission cases and structural parts on more than 50 machines ranging from 300 to 3,500 tons and have an in-house park of more than 300 CNC lathes and machining centers. The company is a renowned supplier for Ericsson and Shenlong and exports to Asia, Europe and the Americas.

* Text and images courtesy of Chongqing Dajiang Millison Co. Ltd., P.R. China