Simulation in Action: Casting Quality, Realizing Innovations, Reducing Costs

The Amstetten Foundry, part of Heidelberger Druckmaschinen AG, produces castings for the world market leader in sheet-fed offset printing presses. In order to maximize quality, stability and profitability of the casting processes, the foundry has used MAGMASOFT® for several years. The software is used throughout the entire process chain and produces quantifiable cost and quality advantages.

The Amstetten factory is one of the most up-to-date and efficient foundries in all of Europe. It acts as a center of excellence for the manufacture of cast-ings for the entire Heidelberg Group, which has annual revenues of 2.3 billion Euros (2009/2010) and 15,000 employees. The cast parts, such as printing press side panels and cylinders, are core elements of the sheet-fed offset presses, which Heidelberger Druckmaschinen AG provides to customers in the print media industry worldwide. “For our customers, just like for ourselves, the decision for Heidelberg is always a decision for quality,” is how Jürgen Schimmel, Head of Pattern & Casting Engineering described the company’s vision, which the foundry implements on a daily basis together with the 450 employees involved in casting production. This is because the quality of each press depends to a significant degree on the quality of the castings produced in Amstetten.

Amstetten’s staff do not just produce castings for the Heidelberg Group: 50 external companies order large and small castings in differing batch sizes from the Amstetten foundry. Free market competition does not just make economic sense; it also serves to ensure that all processes are focused on achieving the highest quality.

“We have a clearly defined goal: economical casting production with consistently high quality. We see casting as part of an overarching process, beginning in design and finishing in reliably functioning, competitive products,” Schimmel said when formulating the mission of the foundry. This level of quality is achieved by continuous IT support over the entire production process, from design of the components and patterns to the stable computer controlled melting and pouring processes. Using MAGMASOFT® the planning epartment Pattern and Casting Engineering bridges the gap between computer-aided product design and actual production. “We use MAGMA simulation technology throughout the entire product and process development process in order to save materials and costs in a highly price-sensitive market, on the one hand, and to drive innovation and optimize component integration on the other,“ explained Hans Frieß, Director of Planning/Material Management.

The following examples show what savings and constructive optimizations were achieved using casting simulation at every step of the process chain:

- Reduction of material input: The optimization of 38 parts (with a total annual production of 31,945 units) with MAGMASOFT® reduced the return scrap by 295 tons in the first year of usage.

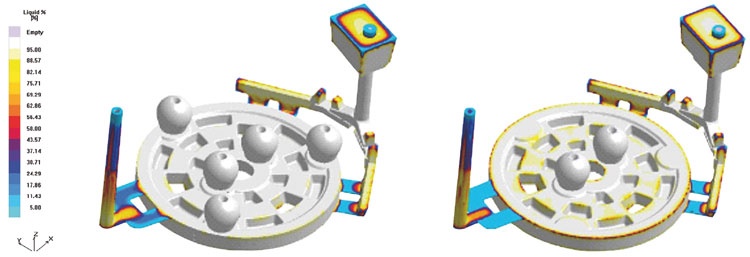

- Molding: Simulation made it possible to use a four-cavity mold instead of a three-cavity mold for roll bearings, while reducing the number of risers at the same time. The yield was enhanced from 16 % to 53 %, the cost per roll bearing decreased by 2.18 Euros.

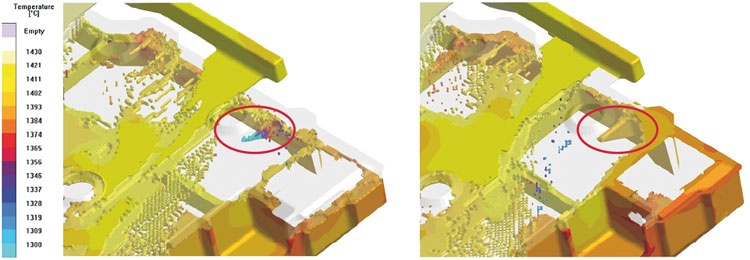

- Optimization of casting rigging: The casting process for a gear wheel was optimized, so that only two risers had to be used instead of five. This meant a significant reduction in the amount of liquid iron required and resulted in savings of 32 Euros per part and 38,000 Euros per year.

- Cooling times: Predictions of both solidification and cooling times for critical parts made it possible to reduce processing times and to optimize the needs for both cooling space and the number of mold frames. This led to reduced operating and logistic costs.

- Savings at shake-out: Using simulation, the gating and riser geometries for the casting of bearing blocks was modified so that they could be removed by breaking them off rather than by sawing. This meant a savings of 5,400 Euros per year for the annual production rate of 12,700 units.

- Reduced finishing effort: Simulation-supported relocation of the ingate reduced the finishing costs of a side part significantly. Welding was needed for 90 % of all raw parts prior to the relocation, but was no longer required afterward.

In the meantime, the cooperation between Amstetten and MAGMA has a track record of eight years. The investment was amortized within just one year instead of the two that had been calculated prior to acquisition. The use of the simulation solution has resulted in faster component development, higher component quality and more economic production. The technology has also assisted the foundry in terms of innovation: using MAGMASOFT® made it possible to begin manufacturing larger, heavier types of components.

Further developments of the software will make more innovation possible. “The deciding factor when choosing MAGMASOFT® was its development potential, as this clearly influences our innovation ability,“ Hans Frieß concluded.