Highlights of MAGMASOFT CC 5.5

What's New in MAGMA CC?

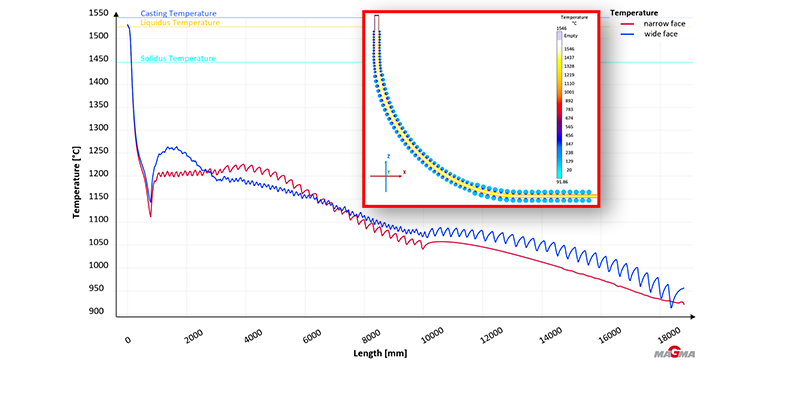

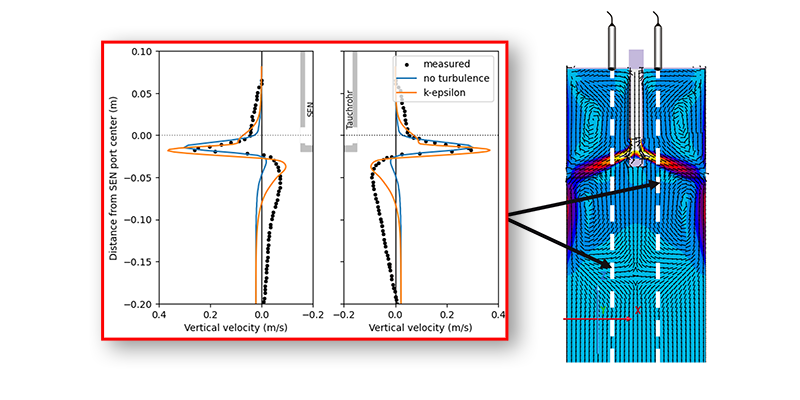

MAGMA CC offers significant innovations and enhancements for the simulation of continuous casting processes. The variable control of the pouring velocity enables the flexible mapping of "stop & go" cycles, including pauses, return strokes and cyclical movements in the withdrawal process. An advanced turbulence model precisely maps the flow behavior, especially in the sump area, and supports the analysis of the flow dynamics in continuous casting.

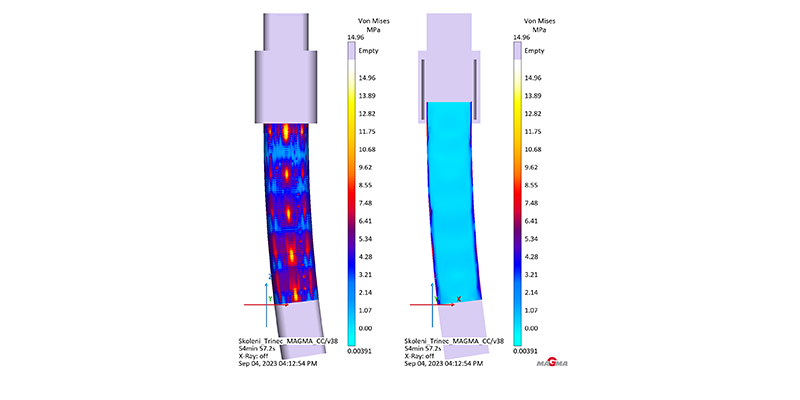

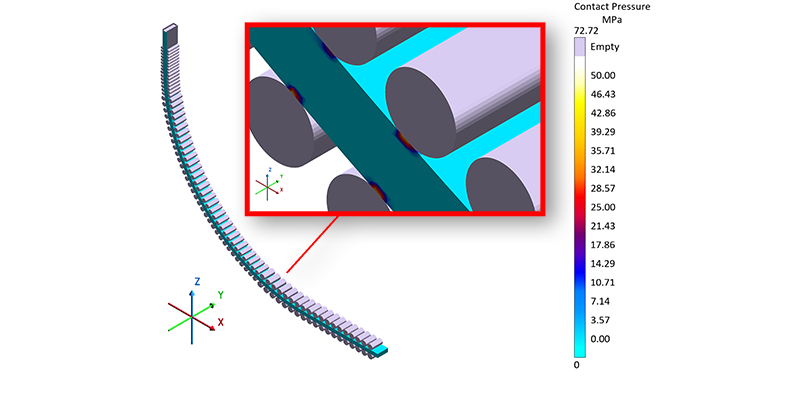

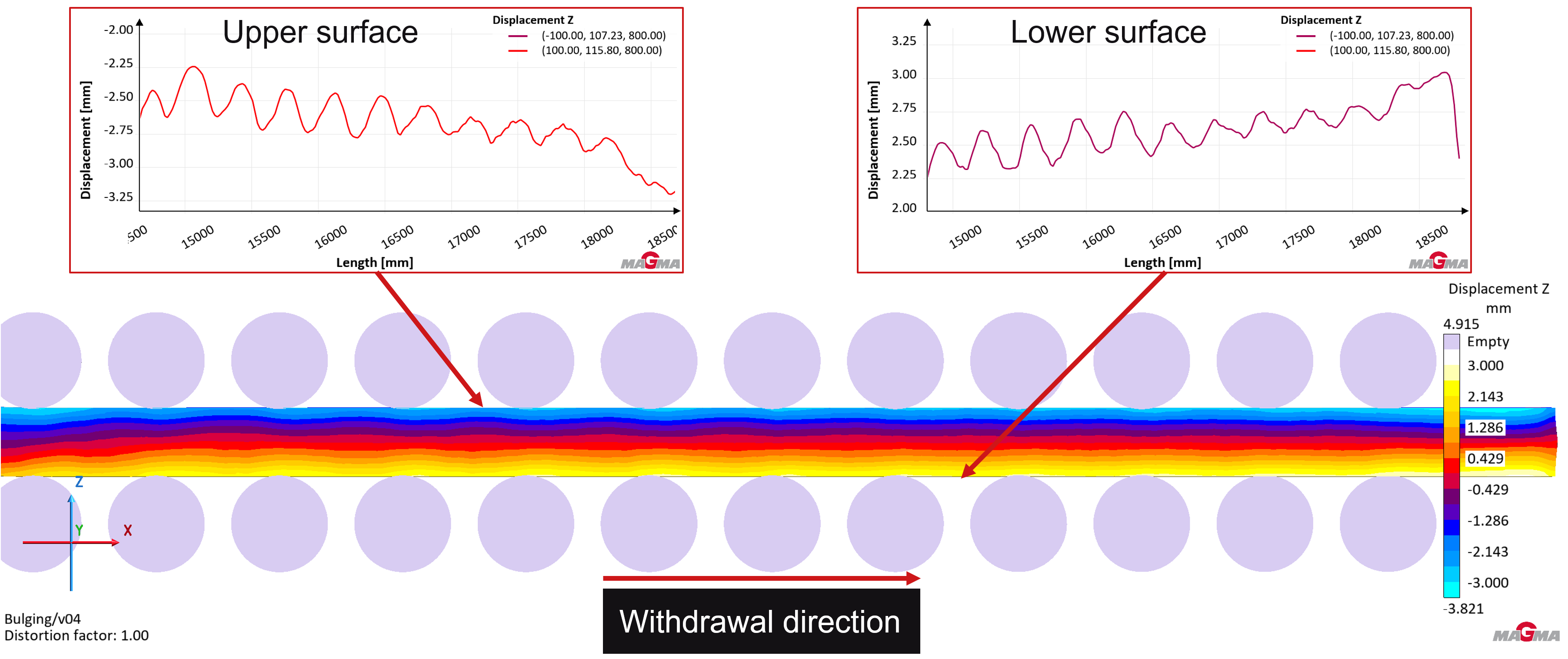

Mechanical influences, such as those caused by guide rollers or the mold, can be examined in detail. Roller position errors can be analyzed in detail to evaluate their influence on the deformation of the strand. This makes it possible to identify potential causes of strand shape deviations and their effects on the strand quality.

In addition, a function for mapping particles (tracer particles) allows analyzing how the melt is distributed across different strands (billets or ingots) via launders. The extended capabilities of MAGMA CC thus provide new quantitative information on process-dependent strand quality and support users in the efficient evaluation of results.

Highlights:

- "Stop & go" control: flexible variation of the pouring velocity, including pauses and return strokes

- Detailed insights: fast creation of a 1D profile of the simulation results for the entire strand length

- Quantitative evaluation of inclusions: particle counting for evaluating the inclusion displacement in different strands over the process time

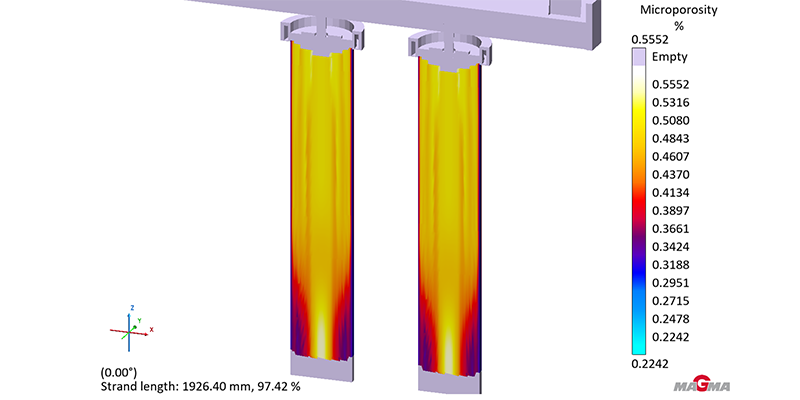

- Microporosity: microporosity prediction by an optimized criterion

- New turbulence model: accurate description of the flow behavior in the launder, in submerged entry nozzles and especially in the sump area

- Influence of the guide rolls: analysis of the mechanical influence of guide rollers on strand deformation and quality, especially in the case of incorrect roller positions

Latest Publication

MAGMASOFT® 6.1 – Efficient Optimization of Processes and Profitability

With new functionalities and extensive enhancements, MAGMASOFT® 6.1 offers comprehensive support for optimizing low pressure die casting processes and facilitates the design of die-cast parts. A specially developed process module for rheocasting and thixomolding processes adds numerous new options for users in core production and continuous casting.

In addition, the newly introduced ECONOMICS Perspective enables, for the first time, a quantitative evaluation and optimization of both costs and CO₂ emissions for all simulation projects, improving both the profitability and the sustainability of all applications.

System Requirements

MAGMASOFT® is available for all suitable current operating systems such as Linux and Windows. MAGMASOFT® can be used on multi-processor computers or massively parallel on cluster computers.