Reoxidation Inclusions in a Stainless Steel Investment Casting

Introduction

Reoxidation inclusions form in steels & stainless steels during mold filling as the metal comes into contact with the atmosphere in the mold. As the surface of the liquid metal is exposed to oxygen, the liquid metal will oxidize & form reoxidation inclusions. MAGMAsteel is able to track the formation, growth & movement of reoxidation inclusions. This helpful prediction can be used to design gating systems & select process parameters that will minimize the damage these harmful defects can cause - poor mechanical properties, failures in service, and costly rework & scrap.

Reoxidation Inclusion Modeling

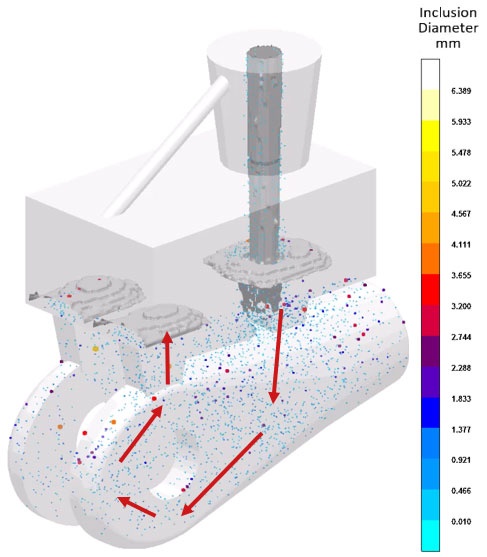

The reoxidation inclusion modeler in MAGMAsteel evenly spaces very small inclusion particles on the surface area of the melt front during each time step of the simulation. As these particles remain in contact with the atmosphere, the oxygen that they contact will cause them to grow. The longer the inclusion particles are in contact with oxygen, the larger they will grow. The particles within the model will also agglomerate or grow as they bump into each other.

This model can be useful for testing different gating approaches to see which approach will minimize inclusion growth and/or ensure that the larger inclusions end up in the runner system, risers or flow offs instead of in critical areas of the casting.

Stainless Steel Investment Casting Case Study

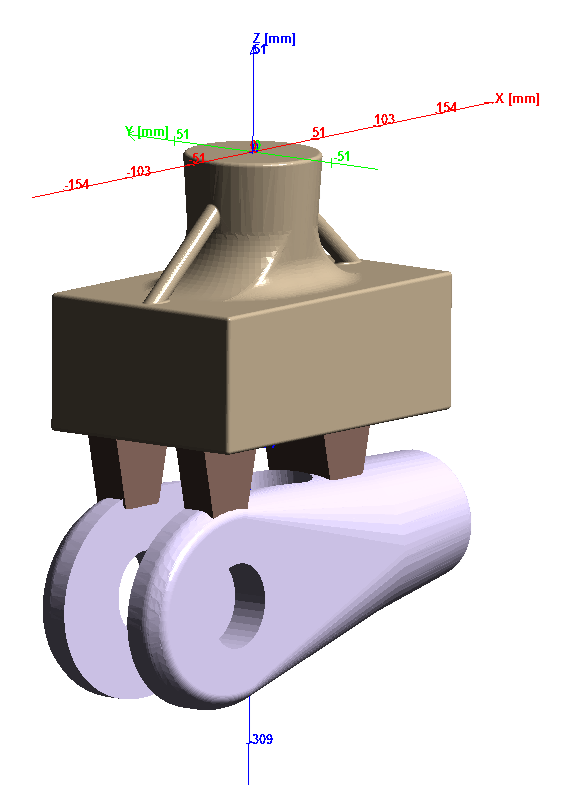

The stainless steel investment casting and the gating system used to produce it below demonstrate how the reoxidation inclusion modeler can be used to test different variables in the casting process to eliminate the scrap and rejects caused by this defect.

In this particular case, the high surface finish requirements, which included a near perfect polished surface, were preventing the foundry from doing weld repair as the welded areas would be visibly different from the rest of the casting after being machined and polished. As a result, reoxidation inclusions were leading to high scrap rates on this part.

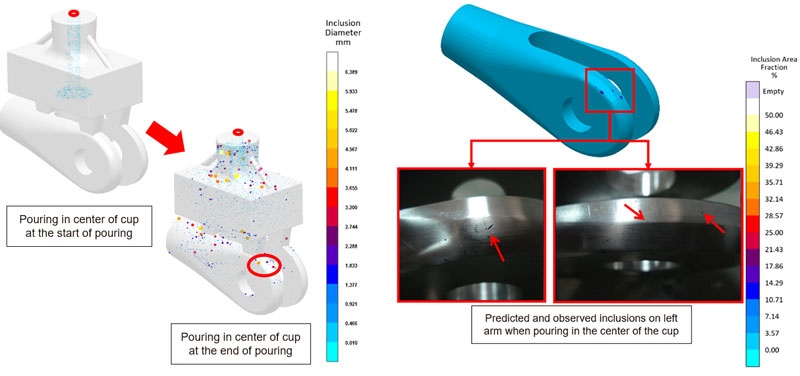

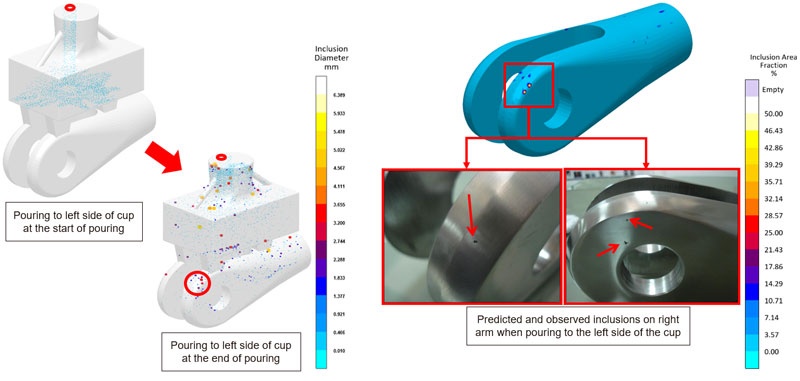

Initially, the foundry was interested in better understanding how different process parameters were impacting the formation and location of the reoxidation inclusions on this casting. Since the castings are being poured from a ladle manually, there was interest in understanding how the location of the stream entering the investment shell would influence inclusion size and location.

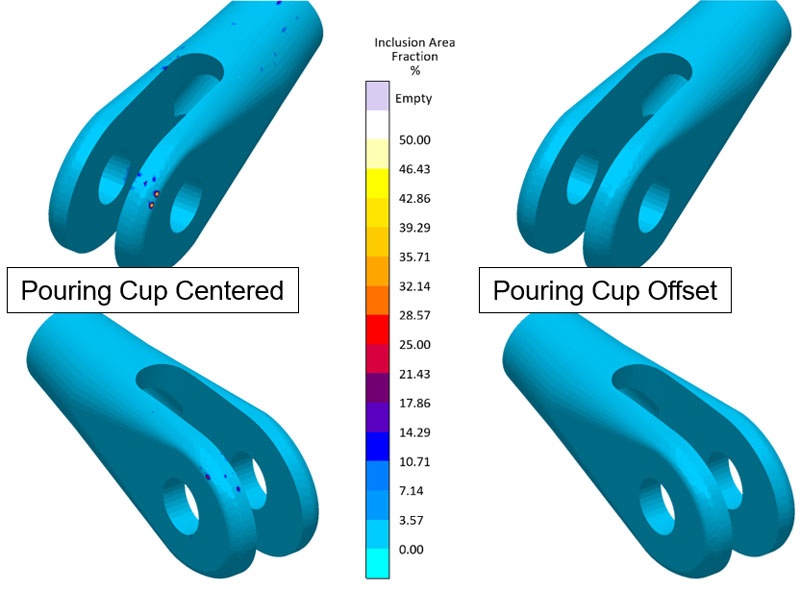

As you can see below, it was found that just a slight movement of the stream coming out of the ladle from the center of the pouring cup to the side of the pouring cup would change the location of the largest inclusions in the casting. In both cases the inclusion location aligned well with production castings.

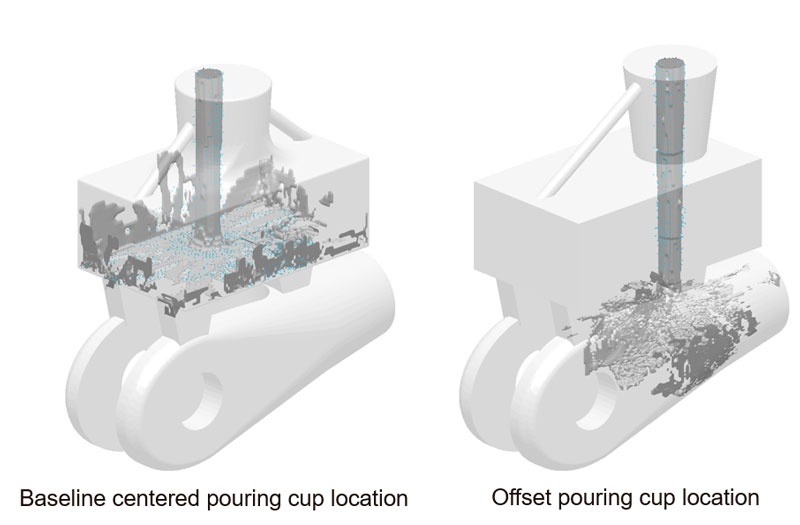

Once the impact of the pouring stream location in the pouring cup was understood, questions arose about where the best location for the pouring cup might be and if it might be possible to flow the inclusions from both arms up in to the top gating when using a different pouring cup location. To test this idea the two locations shown below were tested using the reoxidation inclusion model.

When using the offset pouring cup it was observed that the flow of the metal moved down through the one ingate that was furthest away from the arms and then up into the ingates directly on top of each arm as shown below.

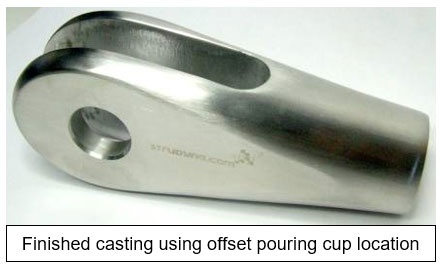

The strategy of using the offset pouring cup to flow the larger inclusions away from the arms and in to the top gating was proved out using the reoxidation inclusion modeler and then with production samples and production castings as shown below. This approach has been adopted by the foundry and the scrap rate for inclusions in the arms are significantly reduced.

Summary

Reoxidation inclusions are difficult to avoid in steel castings and will often times lead to large amounts of rework, scrap, customer returns and undesirable material properties. The reoxidation modeler that is part of the MAGMAsteel module is an essential tool for steel foundry engineers as they seek to design gating systems that will minimize the damage done and costs incurred as a result of reoxidation inclusions in steel castings. The stainless steel investment casting case study demonstrates how the reoxidation inclusion modeler can be used by the foundry engineer to better understand the impact of process parameters and to design gating systems that minimize scrap and rework related to reoxidation inclusions.