Working Under Pressure

Blind risers can only work properly for the limited number of cast alloys with a strong tendency to form a solid skin during solidification, such as steel alloys. This skin formation means that shrinkage in the casting leads to an under-pressure in those areas where feeding is needed. The difference between the higher pressure in the blind riser and the under-pressure in the area to be fed allows blind risers to feed “uphill” into the casting.

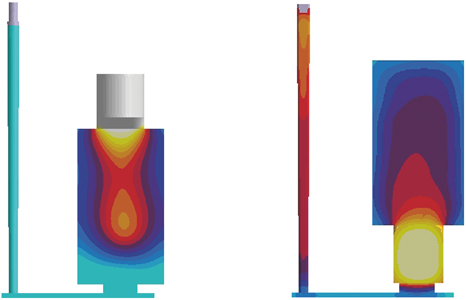

For alloys like ductile iron or aluminum cast in sand, the formation of a strong skin does not occur. This means that blind risers can not be used directly. For them to work, they have to be put under pressure. This can be done by using compressed gas as seen in the figures below.

By considering the effects of the riser pressurization, simulation can be used to determine the correct riser size, working pressure level and time to apply pressure. The simulation results shown here compare the temperatures during solidification for a layout with a blind and with an active riser.