Head Block Distortion

Many large steel castings are produced with large machining allowances, which directly results in higher production costs. One reason for including this overstock material is uncertainty regarding the non-uniform distortion of the casting during solidification and cooling. Looking to reduce costs, Dedini Foundry used simulation to predict distortion and reduce machining allowances as much as possible. They simulated three castings and compared results for the real final dimensions, estimated dimensions and simulated dimensions. One of the simulated castings was a 20.6 ton head block.

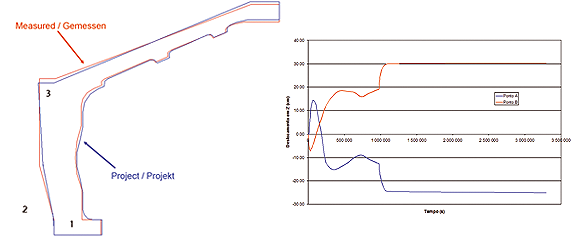

Using simulation, it was possible to virtually follow the displacement to the casting during solidification and cooling of the flanges. The results showed that the flanges distorted up and down in opposite directions, caused by the heterogeneous temperature profile during solidification and cooling. There was also a good correlation between simulated and real final dimensions, with a maximum difference of around 6mm.

Based on these results, it was clear that some of the overstock material could be safely be eliminated, resulting in lower costs and a more competitive position for the foundry.

* Courtesy of Dedini, Brazil