Riser Redesign to Feed Wheel Hub

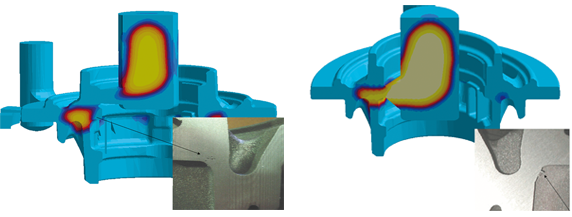

Metalurgica Frum was trying to develop a wheel hub for several months without success. Despite these efforts, they could not avoid a shrinkage defect in a hot spot in the hub. They decided to stop tests on the shop floor and try a new central riser/sleeve design developed and verified using casting process simulation.

The riser was initially placed to feed in the same direction as the hot spot. However, even with a riser and riser neck with the correct thermal modulus, the shrinkage porosity was not fed. The simulation results showed that the bottom of the riser basin was too close to the riser neck, causing the neck to solidify too early. Redesigning the riser neck and the basin, the shrinkage problems were eliminated. In a final simulation, two lateral risers were also removed, increasing the yield from by 10 % and saving two sleeves per mold.