Innovative Process Simulation of Tool Steel Production Processes

Wilfried Schäfer, Götz Hartmann, Erik Hepp, MAGMA GmbH, Aachen, Germany

Abstract

Over many years, the liquid metal flow in steel continuous casting tundishes and molds, the cooling and solidification of the melt and the formation of segregation, as well as stresses and cracks, have been the subject of numerous projects in which the phenomena were analyzed by various measurement techniques, calculations and/or analytical or numerical simulations. The motivation for these efforts was the desire to understand the details of the phenomena influencing the casting process performance and the strand quality, in order to be able to optimize the casting process conditions.

Today, the combination of newest developments in coupled 3D numerical heat and mass transport simulation coupled with computational optimization methods based on genetic algorithms allows new approaches to answering various questions that arise in process optimization.

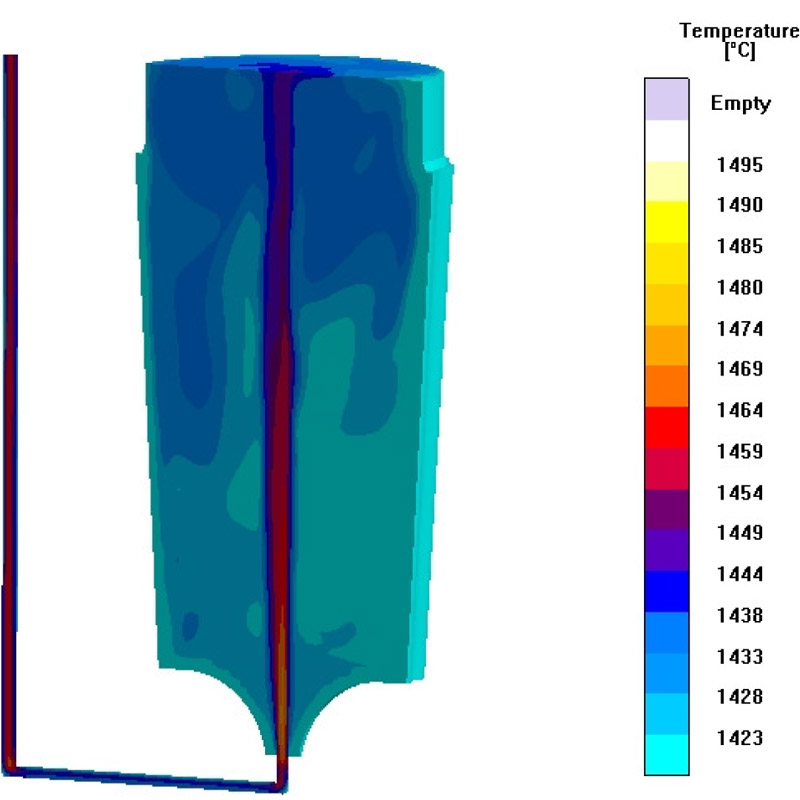

In this contribution, the authors show different examples of the use of genetic algorithms for autonomous multi-objective numerical optimization of the continuous casting process and in the second part of this paper for the prediction of filling, solidification, convection and segregation for a steel ingot of a typical tool steel.

Please read the complete publication in the linked PDF.