Material Combinations in Lightweight Casting Components

Götz Hartmann

Introduction:

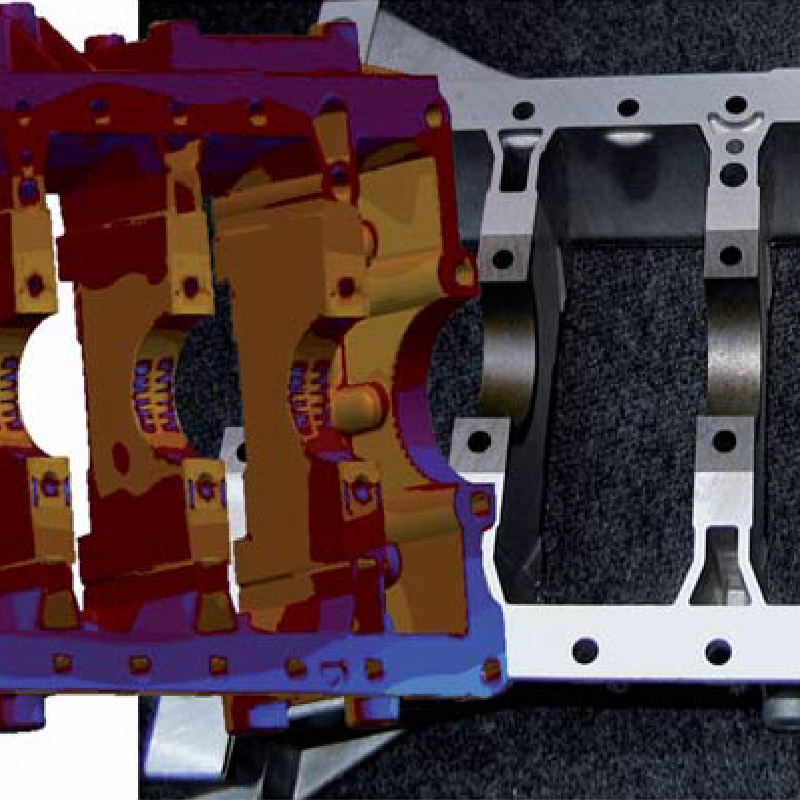

Aluminum und magnesium castings play a major role in light-weight casting. These fields of application are being extended continually, and the specific demands on materials are increasing. More often the mechanical and tribological properties of the casting materials are insufficient, the operating temperatures are too high, or the environment shows a high level of chemical aggression. Local components can then be tailored to specific demands by cast-in inserts mostly made of steel or cast iron, depending on the requirements. During pouring, these inserts cause various and sometimes not uncritical phenomena. For instance, the molten metal is chilled locally, which can block flow paths during mold filling. Non-uniform cooling of the casting causes residual stress, distortion and, in some circumstances, cracks and fractures. The same problems may occur due to the differences in heat conductivity and thermal expansion of the paired materials.

This article shows how possible residual stress, distortion and crack formation can be calculated and reduced, if necessary, even before the first parts are cast or prior to heat treatment.

Please read the complete publication in the linked PDF.

(This article is based on a lecture held at the VDI conference “Simulation im automobilen Leichtbau” in November 2011 in Baden-Baden, Germany)