HIGHLIGHTS OF MAGMAiron 5.5

HIGHLIGHTS & BENEFITS OF MAGMAiron5.5

HIGHLIGHTS OF MAGMAiron 5.5

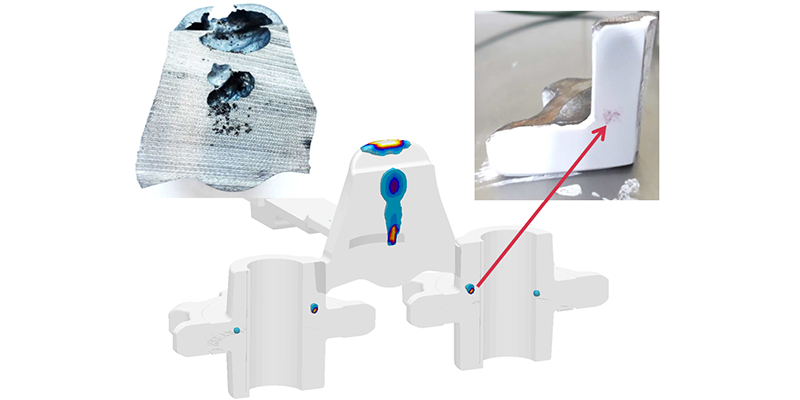

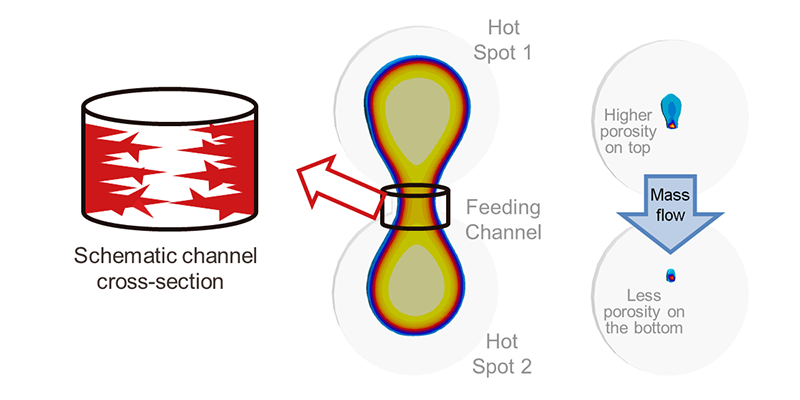

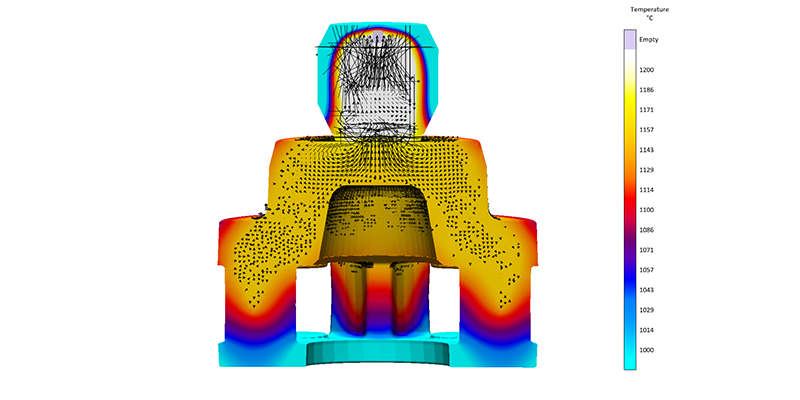

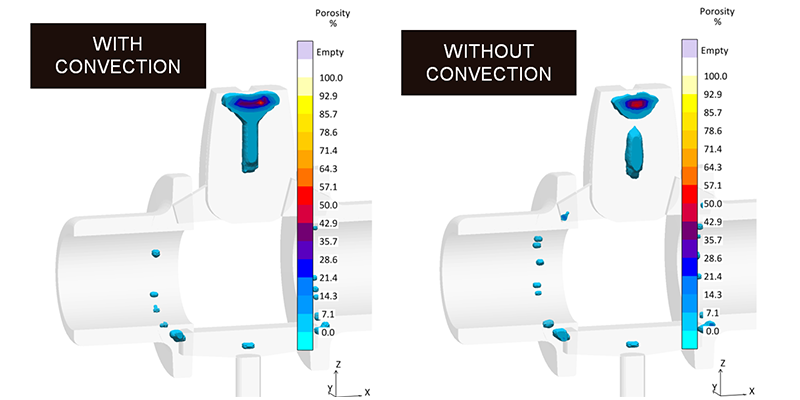

Quantitative prediction of shrinkage related defects with a new powerful feeding model taking into account

- Convective heat transport during solidification

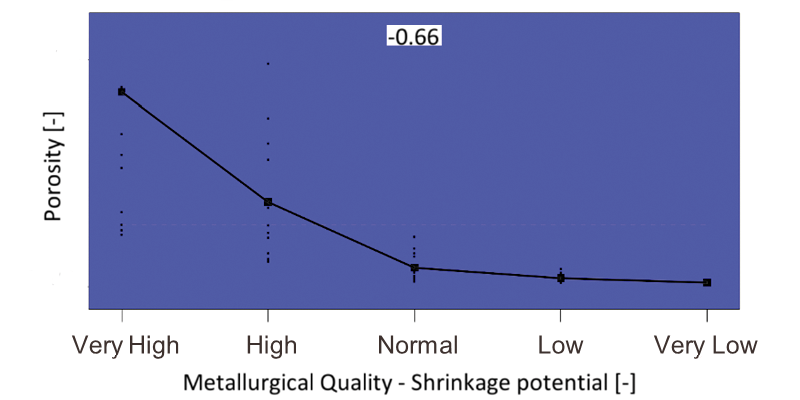

- The metallurgical state of the melt

- Inoculation effects on precipitated eutectic graphite

- Atmospheric and local metallostatic pressure on feeding flow

- Graphite expansion and austenite shrinkage

- Flow resistance in mushy zones during solidification

- Impact of mold stability on porosity

MAIN BENEFITS of MAGMAiron 5.5

MAGMAiron quantitatively predicts microstructure and porosity for cast iron as a function of alloy composition, metallurgical state of the melt and inoculation effects and offers

- Increased safety by accurately predicting porosities

- Robust and optimized gating and feeding designs

- Reduced cost by avoiding scrap through optimized process parameters

- Availability by addressing metallurgical and material specifics for grey, ductile and compacted cast iron grades

When downloading the PDF, please leave your contact data (you will receive the download link by e-mail) and thus agree to the processing and storage of it by MAGMA casting technology GmbH in Aachen. It will not be passed on to third parties. For further information how we process your personal data, please follow this link Privacy Policy.

Latest Publication

MAGMASOFT® 6.1 – Efficient Optimization of Processes and Profitability

With new functionalities and extensive enhancements, MAGMASOFT® 6.1 offers comprehensive support for optimizing low pressure die casting processes and facilitates the design of die-cast parts. A specially developed process module for rheocasting and thixomolding processes adds numerous new options for users in core production and continuous casting.

In addition, the newly introduced ECONOMICS Perspective enables, for the first time, a quantitative evaluation and optimization of both costs and CO₂ emissions for all simulation projects, improving both the profitability and the sustainability of all applications.

System Requirements

MAGMASOFT® is available for all suitable current operating systems such as Linux and Windows. MAGMASOFT® can be used on multi-processor computers or massively parallel on cluster computers.