Key Benefits of MAGMA ECONOMICS:

-

Upfront Achievement of Goals:

Realize quality and cost targets even before the first casting is produced. -

Informed Decision-Making:

Access transparent and quantitative technical and commercial information to support better decision-making. -

Optimal Resource Utilization:

Seamlessly integrated with MAGMA’s autonomous engineering to identify the best operational conditions and balance resource investment and profitability. -

Environmental Impact Awareness:

Understand the direct link between resource consumption and your CO2 footprint. -

Customized Efficiency:

Tailor the system with custom templates to meet your specific process and business requirements. -

Scalable Implementation:

Deploy the solution at the part, department, or corporate level, ensuring adaptability to your organization’s structure. - Comprehensive Evaluation:

Simultaneously assess casting quality, process robustness, and cost/resource considerations.

Maximize Casting Exellence and Cost Effinciency

MAGMA ECONOMICS is a new solution designed to complement MAGMASOFT®, the world’s leading technical decision support and optimization tool for casting quality and processes. With MAGMA ECONOMICS, users can seamlessly integrate information automatically provided by MAGMASOFT® with cost and resource consumption data for any simulated engineering solution.

This innovative approach to combining technical expertise with economic insight allows both technical and economic goals to be pursued simultaneously, making MAGMASOFT® a powerful management tool for users and decision-makers alike.

Key Features of MAGMA ECONOMICS:

Comprehensive Planning and Optimization

Leverage MAGMASOFT® to analyze and compare different simulated versions while using statistical tools to derive concrete measures for quality, productivity, material efficiency, and energy consumption.

Cost and Resource Integration

Bridge the gap between technical simulations and real-world implications by automatically linking MAGMASOFT® information with costs and resource consumption.

Dual Focus on Technical and Commercial Targets

Simultaneously pursue desired technical and commercial goals. Align simulations with cost and resource data to make informed decisions that optimize both.

Empowering Management Tool

Transform MAGMASOFT® into a valuable management tool, empowering users and decision-makers to drive quality, productivity, and profitability.

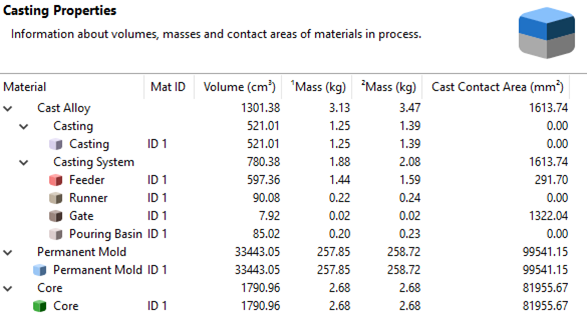

Information Available for MAGMA ECONOMICS

The following essential information available within MAGMASOFT® provides for a comprehensive assessment of cost and resource objectives in MAGMA ECONOMICS while maintaining the required quality:

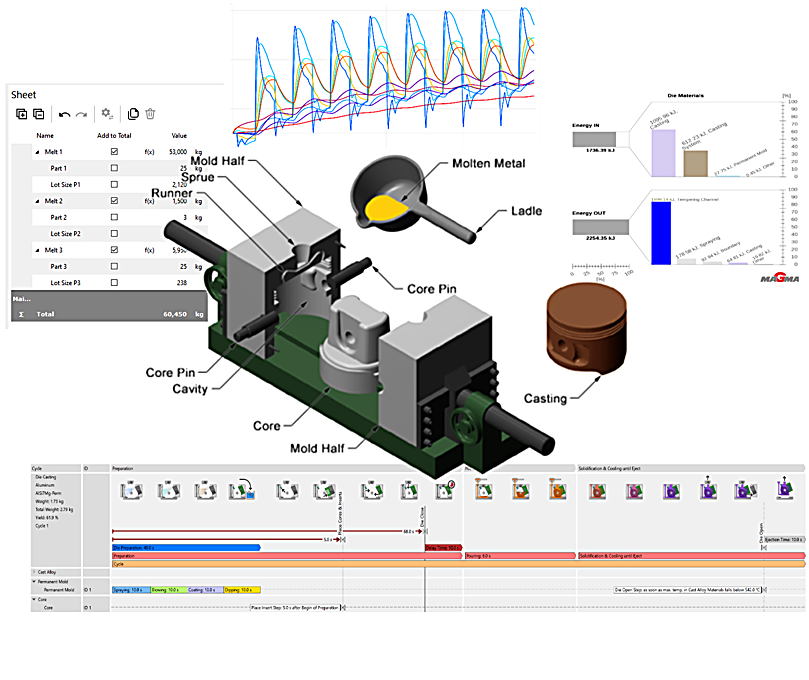

Casting Information Centralized

MAGMA ECONOMICS integrates data from various elements of the casting process, including casting/core components, molds/tools, machines, and materials. Quantitative data on volumes, quantities, masses, surfaces, and interfaces provide a comprehensive understanding of the process.

Process Insights

MAGMA ECONOMICS considers essential process data such as time-related metrics, media usage and consumables. This comprehensive view helps to optimize decision-making.

Unique MAGMASOFT® Output

MAGMASOFT® generates technical information that serves as the basis for evaluating economic factors in MAGMA ECONOMICS. This output includes casting times, feeding requirements, required cycle times (including shake-out/ejection times, cooling times, and curing/drying times) as well as quantities of heat and energy consumption within the system.

Flexible and Fully Integrated With MAGMASOFT®

MAGMA ECONOMICS can be customized to the needs of your organization and is fully integrated with MAGMASOFT®. This allows you to create value for stakeholders at all levels of your organization that use or benefit from simulation results.

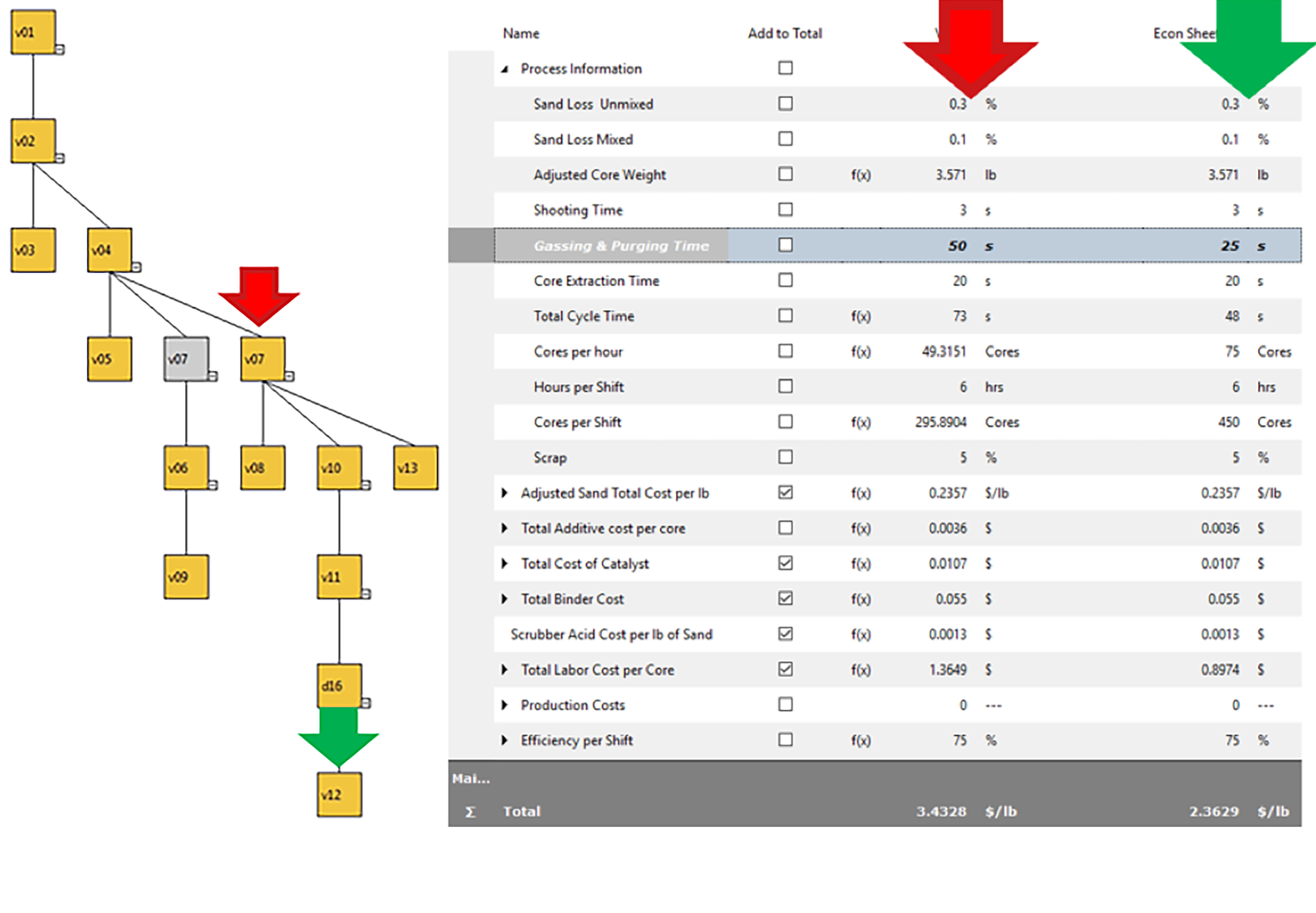

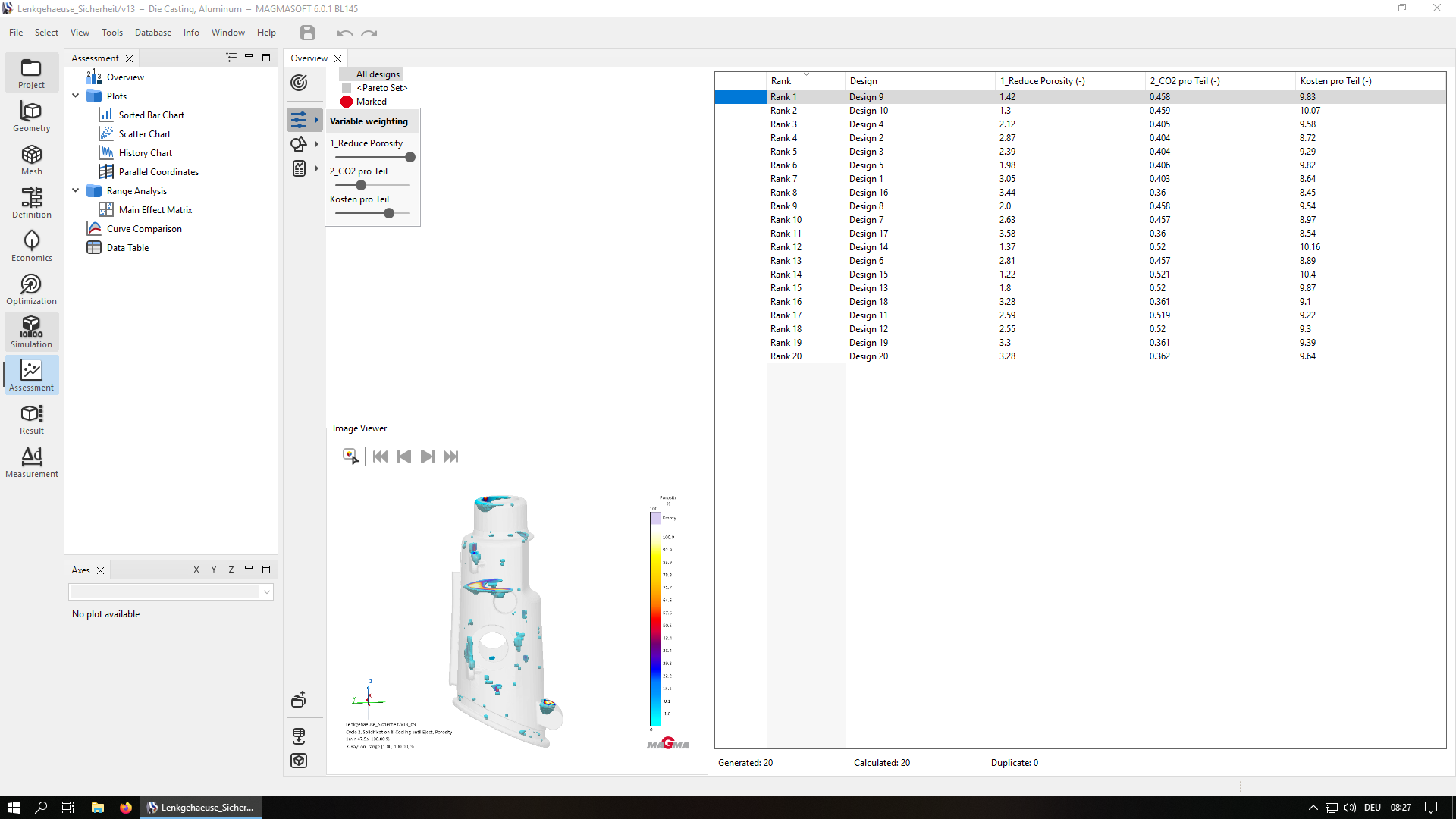

Evaluate Casting Designs and Virtual Test Plans

Explore different simulated casting designs, virtual test plans (DoE), and optimizations and evaluate them in terms of technical feasibility and quality as well as with respect to resource and cost targets. Gain valuable insight into the economic impact of different design choices.

Assess the Impact of Cost Drivers

Analyze the impact of different cost drivers on existing projects without the need for further simulations. MAGMA ECONOMICS allows you to evaluate and optimize cost parameters offline or inline, enabling you to make informed decisions based on real-time cost analysis.

Customizable Templates for Different Needs

Choose from a variety of templates offered by MAGMA ECONOMICS and customize them to meet your specific process requirements and tasks. Whether your focus is at the part, department, or corporate level, you can adjust the level of detail and granularity to meet your objectives.

Easy Communication

The information provided by MAGMA ECONOMICS can be easily displayed in MAGMAinteract®, providing a user-friendly display for the shop floor or for management purposes. Keep all stakeholders informed and involved in the optimization process.

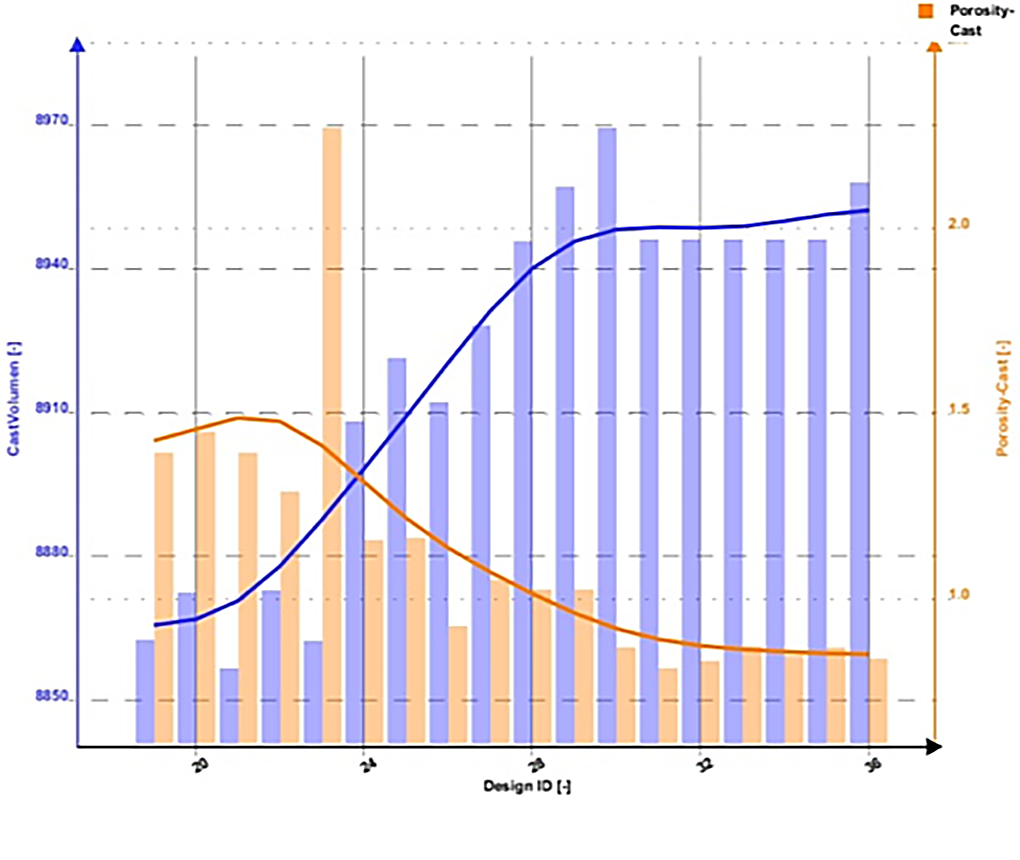

품질 vs. 수율

생산성과 품질 간 균형점을 찾아 최적의 수율 달성

사이클 타임 vs. 에너지 소비

생산성은 높이면서 에너지 소비는 최소화하는 전략 수립

일반 압탕 vs. 발열 슬리브

요구되는 주조 품질에 맞춰 가장 경제적이면서 효율적인 급탕 방법을 결정

냉금 사용 vs. 추가 급탕

주물에 필요한 품질을 달성하기 위해 냉금을 사용하는 경우와 추가 급탕을 적용하는 경우의 경제성 평가

금형 설계 및 가스 발생률

코어 가스 처리를 최적화하여 비용을 최소화하고 전반적인 주조 성능을 개선

코어 박스 예열 vs. 가스 흐름

무기 코어에 대한 코어 박스 예열과 가스 흐름 간의 균형 확인

패턴 플레이트 설계 및 생산 시간

연간 비용 절감과 생산 효율성 사이의 최적화된 방안 도출

부품당 생산량 및 비용

다양한 생산 조건에서의 경제적 비용을 파악하고 방안을 최적화할 수 있도록 지원

CO2 배출량 분석

다양한 생산 조건에서의 탄소 배출량을 수치화할 수 있습니다. 사용자의 주조 공정이 자원과 환경에 미치는 영향에 대해 이해하고 지속 가능한 개발을 지원합니다.

비용 절감 vs. 시뮬레이션 작업량

기술적 평가에만 의존했던 기존 방식에서 벗어나, 경제성을 함께 고려해 추가적인 절감 기회를 발견할 수 있습니다.